The Caterpillar 3208 TA Marine Engine is designed to meet the rigorous demands of the marine environment. Whether you're operating a commercial fishing vessel, a yacht, or a workboat, this engine offers unmatched performance and versatility. With its turbocharged and aftercooled design, the 3208 TA delivers impressive power, ensuring you can navigate through rough waters and reach your destination quickly and efficiently.

But it doesn't stop there – the Caterpillar 3208 TA Marine Engine is also highly fuel-efficient, ensuring you can make the most of every drop of fuel. Its advanced engine management system optimizes fuel delivery and combustion, resulting in reduced emissions and lower operating costs. With enhanced fuel economy, you can extend your range and spend more time on the water enjoying the journey.

Caterpillar 3208 TA Engine Specs

- V-8, Four-Stroke-Cycle Diesel;

- Emissions - IMO compliant;

- Bore — mm (in) - 114.3 (4.5);

- Stroke — mm (in) - 127 (5.0);

- Displacement — L (cu in) - 10.4 (636);

- Rotation (from flywheel end) - Counterclockwise;

- Compression Ratio

- 210 hp - 16.5:1;

- 435 hp - 15.5:1; - Capacity for Liquids — L (U.S. gal);

- Cooling System (engine only);

- DINA - 47.3 (12.5);

- DITA - 56.0 (14.8);

- Lube Oil System (refill);

- DINA - 12.0 (3.2);

- DITA - 15.0 (4.0); - Oil Change Interval — hrs - 250;

- Engine Weight, Net Dry (approx) — kg (lb);

- 210 hp - 722 (1592);

- 375 hp - 772 (1702);

- 435 hp - 899 (1982).

Cat 3208 TA Engine Standart Equipment

- Air Intake - dry type, single stage air cleaner; AirSep for 435 & 375 hp Classic Editions;

- Alternator - belt driven, 51 Amp, 12 Volt;

- Cooling - thermostats, jacket water pump, auxiliary sea water pump, expansion tank, coolant recovery tank (DITA), marine gear oil cooler (DITA: sea water cooled, DINA: jacket water cooled), engine mounted heat exchanger;

- Exhaust system - exhaust manifold and turbocharger, water cooled, 152 mm (6 in) round flanged outlet (DITA); exhaust manifold, water cooled, dual 64 mm (2.5 in) round flanged threaded outlets (DINA);

- Flywheel and flywheel housing - SAE No. 2, SAE No. 3;

- Fuel - filter, priming pump;

- Governor - mechanical;

- Instrumentation - tachometer drive, wiring harness;

- Lubricating - oil filter, filler, oil level gauge, crankcase breather (DITA), positive crankcase ventilation valve (DINA);

- Starting - 12V electric;

- Support - front.

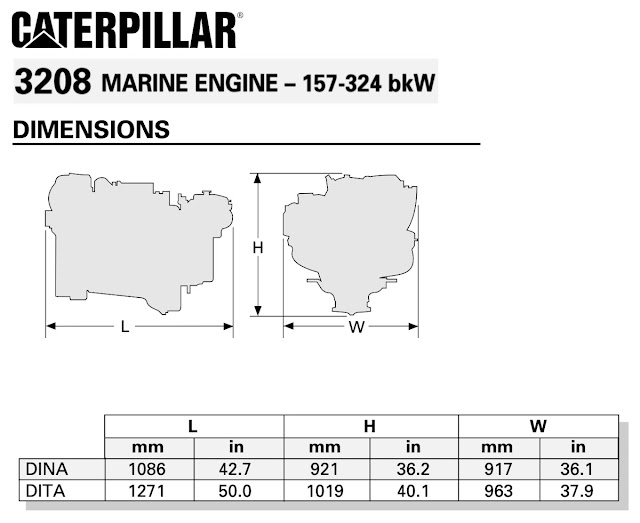

Caterpillar 3208 TA Engine Dimentions

In addition to its performance and efficiency, the Caterpillar 3208 TA Marine Engine is built to withstand the harsh marine environment. With its rugged construction and durable materials, this engine can handle the toughest conditions, delivering reliable operation day after day. Its robust design also minimizes maintenance and downtime, keeping your vessel on the water and maximizing productivity.

When it comes to marine engines, reliability is paramount, and Caterpillar understands this better than anyone. With the Cat 3208 TA Marine Engine, you can have peace of mind knowing you have a trusted and proven engine dedicated to delivering uncompromising performance, efficiency, and dependability.

From commercial applications to recreational boating, the Caterpillar 3208 TA Marine Engine is the ideal choice for any marine vessel. Experience the power, efficiency, and reliability that Caterpillar is known for – choose the Cat 3208 TA Marine Engine and set sail with confidence.

Cat 3208 TA Marine Engine Key Features

The Caterpillar 3208 TA Marine engine is a popular choice for marine applications and has several advantages and key features:

- Power and Performance: The Caterpillar 3208 TA Marine engine is known for its robust power and performance. It is designed to deliver high torque at low engine speeds, making it suitable for heavy-duty marine applications.

- Reliability: Caterpillar has a reputation for manufacturing high-quality and reliable engines, and the 3208 TA is no exception. It is built to withstand the harsh marine environment, ensuring long-lasting performance and minimal downtime.

- Fuel Efficiency: This engine is relatively fuel-efficient for its size and power output. It has a good power-to-weight ratio, which helps reduce fuel consumption and operating costs over time.

- Compact Size: The compact design of the Caterpillar 3208 TA Marine engine makes it easier to install in various marine vessels, especially those with limited engine room space. This advantage allows for more flexibility in vessel design and layout.

- Easy Maintenance: The engine is designed with accessibility in mind, making it easier for routine maintenance and servicing. This helps reduce maintenance costs and downtime associated with engine maintenance.

- Adaptability: The Caterpillar 3208 TA Marine engine can be customized and adapted to suit different applications and requirements. It offers a range of optional features and accessories, such as cooling systems, instrumentation, and exhaust systems, allowing for greater flexibility in marine installations.

- Size and Weight: Although it is relatively compact for its power output, the Caterpillar 3208 TA Marine engine is still a sizable and heavy engine. This can limit its use in smaller vessels or situations where weight restrictions are critical.

- Noise and Vibration: This engine can produce considerable noise and vibration, which may require additional soundproofing measures in the vessel's design. This can add cost and complexity to the installation process.

When comparing the Caterpillar 3208 TA Marine engine with similar models, it's important to consider factors such as power output, fuel consumption, reliability, and adaptability to specific vessel requirements. Some comparable engines in the market include the Cummins QSB, Yanmar 6AY, and Volvo Penta D13. Conducting a detailed analysis of these engines' specifications and consulting with experts can help determine which engine is the best fit for a specific marine application.

Comments