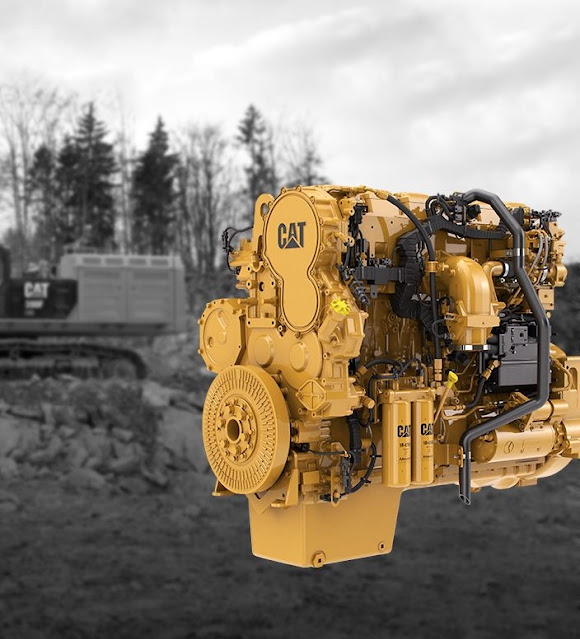

The Cat® C18 Diesel Engine is offered in ratings ranging from 429-522 bkW (575-700 bhp) @ 1800-1900 rpm. Industries and applications powered by Cat C18 engines include: Agriculture, Ag Tractors, Bore/Drill Rigs, Chippers/Grinders, Compactors/Rollers, Compressors, Construction, Cranes, Forestry, General Industrial, Hydraulic Power Units, Irrigation Equipment, Material Handling, Mining, Mobile Earthmoving Equipment, Paving Equipment, Pumps, Shovels/Draglines, Surface Hauling Equipment and Trenchers.

Cat C18 Specs

With plenty of options to keep the engine package size to a minimum, the Cat C18 is a fully-configurable engine giving owners the power to customize based on a variety of applications.

Power Rating

- Maximum Power - 800 HP

- Maximum Torque - 2736 lb-ft @ 1300 rpm

- Rated Speed - 1800-2000

- Minimum Power - 575 HP

- Emission Standards - EU Stage V

Engine Specifications

- Engine Configuration - In-Line 6

- Bore - 5.7 in

- Stroke - 7.2 in

- Displacement - 1104.5 in³

- Compression Ratio - 16.0:1

- Aspiration - Turbocharged-Aftercooled (TA) or Series Turbocharged Aftercooled (TTA)

- Combustion System - Direct Injection

- Rotation from Flywheel End - Counterclockwise

- Aftertreatment - DOC or DOC+DPF+SCR

Dimensions (Approximate)

- Length - 56.6 in

- Width - 44.6 in

- Height - 53.4 in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments - 3785 lb

PETU Dimensions - Tier 4 Final Only

- Length - 33.6 in

- Width - 11.3 in

- Height - 21.7 in

- Weight - 42.8 lb

- Volume Capacity - 51.1 qt (US)

With a DEF capacity of 93.7 liters and 5,000-hour service intervals, the Cat C18 also features transparent regeneration technology giving owners the power to stay more productive - when its needed the most.

Whether you own a fleet of machines or even just one, it's important to keep lifetime costs of the engine low. The Cat C18 aims to do just that through a combination of technologies that only require 500-hour service intervals and optimize fluid consuption levels to be the most effective and efficient no matter the application.

Clean air isn't just about creating a better world, it's about work site saftey as well. That's why the Cat C18 features a clean emissions module that uses DOC, DPF and SCR tecnologies to keep the engine running cleaner than ever before.

The Cat C18 Industrial Diesel Engine offers a range of advantages and key features that make it a preferred choice for industrial applications. Let's delve into its notable benefits:

Cat C18 Industrial Diesel Engine Advantages:

- Power and Performance: The Cat C18 engine is known for its impressive power output and performance capabilities. With a power range of 429 kW (575 hp) to 634 kW (850 hp), it delivers robust and reliable performance, ensuring optimal productivity in a variety of industrial applications.

- Advanced Technology: The C18 engine incorporates advanced technologies to enhance its efficiency and performance. It features a high-pressure common rail fuel system, advanced electronic control modules, and precise fuel injection for optimized fuel combustion, resulting in improved fuel efficiency and reduced emissions.

- Durability and Reliability: Built with rugged construction and high-quality components, the C18 engine is renowned for its durability and reliability. It undergoes rigorous testing to ensure it can withstand demanding operating conditions, reducing downtime and maintenance costs.

- Fuel Efficiency: Caterpillar has designed the C18 engine with fuel efficiency in mind. It utilizes advanced electronic controls and fuel system optimization to deliver efficient fuel combustion and reduce overall fuel consumption. This translates to cost savings and minimized environmental impact.

- Emissions Compliance: The C18 engine meets stringent emissions regulations, including EPA Tier 4 Final and EU Stage V standards, without the need for complicated aftertreatment systems. It achieves compliance through advanced combustion technologies and precise control of fuel and air mixture.

- Easy Maintenance and Serviceability: The C18 engine is designed for easy maintenance and serviceability. It features easily accessible service points, user-friendly diagnostic interfaces, and remote monitoring capabilities, enabling efficient maintenance planning, reduced downtime, and faster troubleshooting.

When comparing the Cat C18 engine to similar models, it stands out for its optimal balance of power, fuel efficiency, and emissions compliance. It offers a competitive power range and fuel consumption profile, ensuring productivity while keeping operating costs in check. Additionally, Caterpillar's renowned global service network, engineering expertise, and comprehensive parts availability enhance the overall value of the C18 engine, making it a trusted choice for various industries.

It's important to note that one potential disadvantage of the Cat C18 engine is its size and weight, which may limit its suitability for applications with space or weight constraints. However, these considerations are outweighed by the engine's performance, durability, fuel efficiency, and emissions compliance, making it a favorable choice for a wide range of industrial applications.

Comments