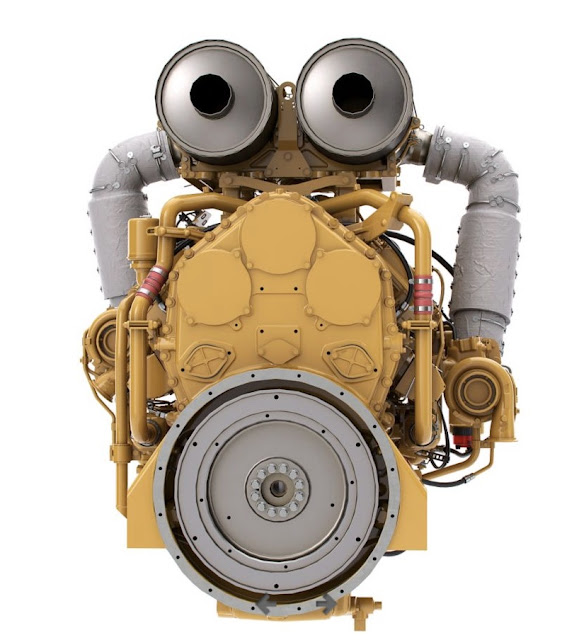

Introducing the powerhouse of industrial machinery - the Caterpillar C32 Industrial Diesel Engine. Designed to conquer the most demanding applications with unwavering performance, this remarkable piece of engineering exemplifies the epitome of strength, efficiency, and reliability. With a heritage deeply rooted in Caterpillar's commitment to excellence, the C32 engine stands tall as a beacon of innovation, delivering unparalleled power and productivity to the industrial world.

Whether driving heavy machinery, generating electrical power, or propelling marine vessels, this robust diesel engine sets new benchmarks for performance, fuel efficiency, and durability. From its cutting-edge technology to its unwavering capability, the Caterpillar C32 Industrial Diesel Engine heralds a new era of industrial prowess, empowering industries worldwide to achieve greater feats and reach new heights of productivity.

Cat C32 Specs

Brace yourself for the extraordinary, as we delve into the heart of this engineering marvel, ready to unveil the unparalleled power and precision that define the Caterpillar C32 Industrial Diesel Engine.

Cat C32 Power Rating

- Maximum Power - 1200 HP

- Maximum Torque - 4056 lb-ft @ 1200 rpm

- Rated Speed - 1800 rpm

- Minimum Power - 1000 HP

Caterpillar C32 Industrial Diesel Engine Specifications

- Engine Configuration - V-12

- Bore - 5.7 in

- Stroke - 6.4 in

- Displacement - 1958.9 in³

- Compression Ratio - 15.0:1

- Emission Standards - U.S. EPA Tier 4 Final

- Aspiration - Twin Turbocharged Aftercooled (TTA)

- Combustion System - Direct Injection

- Rotation from Flywheel End - Counterclockwise

- Aftertreatment - DOC

Cat 32 Engine Dimensions (Approximate)

- Length - 73.8 in

- Width - 63 in

- Height - 53.9 in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments - 6625 lb

Caterpillar C32 Standard Equipment

Air Inlet System

- Turbocharged

- Air-to-Air Aftercooled

Control System

- Electronic control system

- Over-foam wiring harness

- Automatic altitude compensation

- Power compensated for fuel temperature

- Configurable software features

- Engine monitoring system SAE J1939 broadcast and control

Cooling System

- Thermostats and housing, vertical outlet

- Jacket water pump, centrifugal

- Water pump, inlet

Exhaust System

- Exhaust manifold, dry

- Optional exhaust outlet

Flywheels and Flywheel Housing

- Choice of SAE No. 0 or SAE No. 1 flywheel housing

Fuel System

- MEUI injection

- Fuel filter, secondary (2 micron)

- Electronic fuel priming

Lube System

- Open crankcase ventilation system

- Oil cooler

- Oil filler

- Lube oil filter

- Rear sump oil pan

- Oil dipstick

- Gear driven oil pump

General

- Paint: Caterpillar yellow, with optional colors available at request

The Caterpillar C32 Industrial Diesel Engine boasts a multitude of advantages and key features that set it apart in the world of heavy-duty machinery. Here are some notable benefits:

- Powerhouse Performance: The C32 engine delivers impressive power, making it ideal for tackling demanding industrial applications. With a power range of 746 kW (1000 hp) to 895 kW (1200 hp), this engine offers exceptional torque and acceleration, ensuring optimal performance even under heavy loads.Advanced Technology: Caterpillar has equipped the C32 engine with state-of-the-art technology to enhance its efficiency and reliability. It incorporates advanced fuel system components, including high-pressure common rail (HPCR) fuel injection, which optimizes fuel combustion and enhances fuel efficiency while minimizing emissions.

- Fuel Efficiency: The C32 engine is designed to maximize fuel efficiency, helping businesses reduce operating costs and minimize environmental impact. It features advanced electronic control systems that optimize fuel delivery based on load and operating conditions, ensuring optimal combustion and fuel consumption.

- Durability and Reliability: Built to withstand harsh operating conditions, the C32 engine is renowned for its exceptional durability and reliability. Its robust construction, high-quality materials, and rigorous testing ensure longevity and minimize downtime, making it a trusted choice for demanding industrial applications.

- Easy Maintenance: The C32 engine is designed with ease of maintenance in mind. It incorporates features such as easily accessible service points, a user-friendly diagnostic interface, and the option for remote monitoring, enabling efficient maintenance planning and minimizing downtime.

- Versatile Applications: The C32 engine is a versatile powerhouse suitable for a wide range of applications. From powering heavy machinery, such as mining trucks, excavators, and drilling rigs, to driving electrical generators or propelling marine vessels, this engine adapts seamlessly to various industrial needs.

- When compared to similar models, the Caterpillar C32 engine stands out with its robust performance, fuel efficiency, and durability. It offers a broader power range, allowing for greater flexibility in meeting different application requirements. Additionally, Caterpillar's reputation for engineering excellence and the extensive global support network further enhance the value proposition of the C32 engine, making it a trusted choice for businesses worldwide.

Comments